Ever wondered why the seemingly straightforward task of routine maintenance can often morph into a complex puzzle of unexpected hurdles? The truth is, the world of maintenance is a dynamic environment, where the best-laid plans can quickly unravel.

Now, you might initially perceive routine maintenance as a simple checklist of tasks. However, it transcends mere procedural steps; it's the bedrock upon which operational efficiency and financial stability are built. It's about ensuring that operations are running smoothly, that major, costly repairs are avoided, and that the rhythm of productivity is maintained. Yet, the unexpected is a constant companion, and thats precisely where the challenges emerge. These challenges necessitate adaptability, foresight, and a proactive approach.

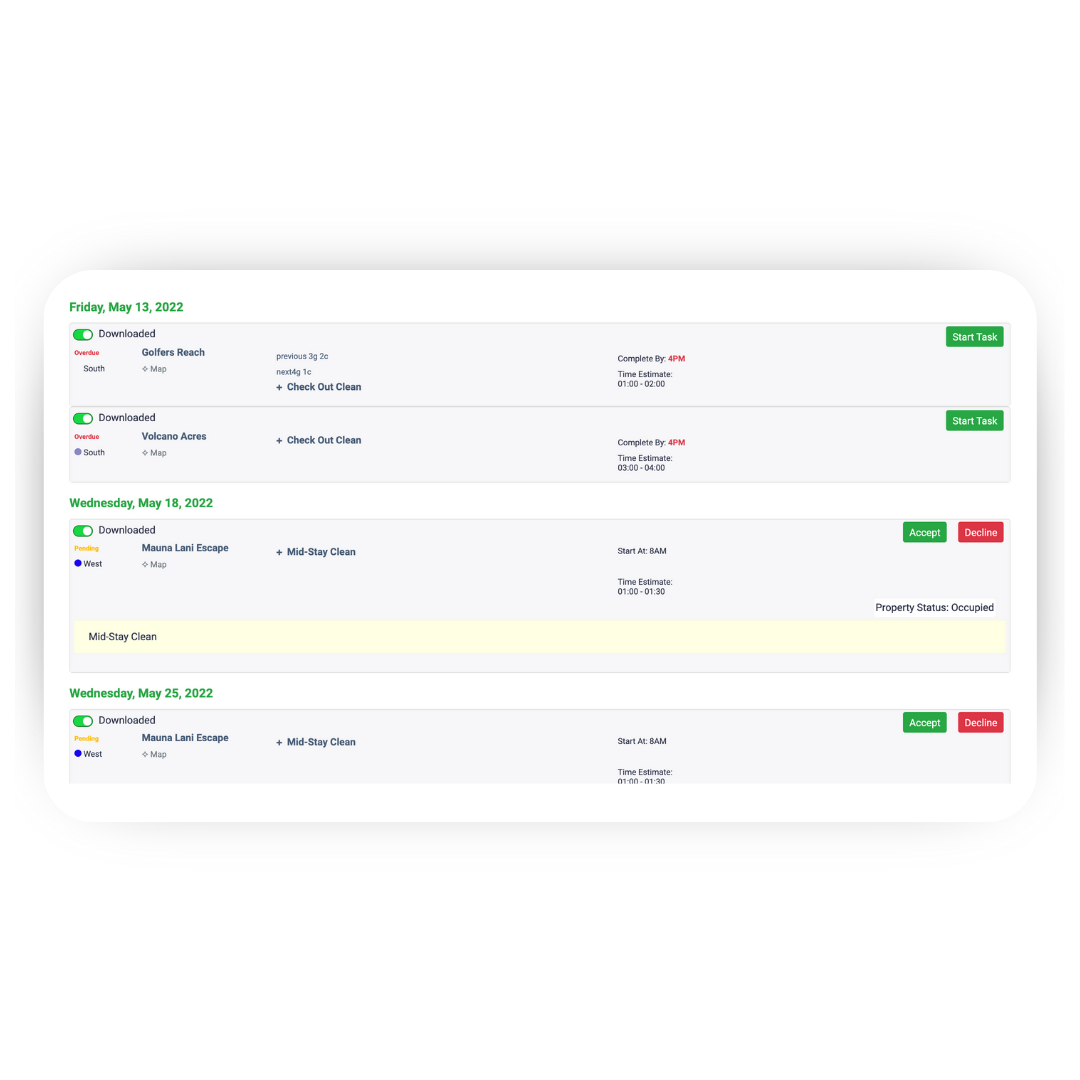

| Aspect | Details |

|---|---|

| Routine Maintenance Definition | The systematic process of regularly inspecting, servicing, and repairing equipment to maintain optimal operational condition and prevent failures. |

| Primary Objective | Preventing major equipment failures, extending lifespan, improving efficiency, and reducing overall operational costs. |

| Key Benefits | Enhanced equipment reliability, increased productivity, minimized downtime, cost savings, and improved safety. |

| Common Challenges | Resource constraints (manpower, tools), equipment failures, time management limitations, weather-related disruptions, and supplier delays. |

| Strategic Approach | Proactive planning, risk assessment, contingency planning, investment in team training, and the incorporation of technological advancements. |

For further reading, you can refer to the following resource: Wikipedia.

- Times Health Mag Your Guide To Smarter Health Choices Wellness

- Master Money Management On Ubettemecom Your Guide To Success

The core of any operational system relies on routine maintenance. It's the diligent process of regularly checking, servicing, and repairing equipment, ensuring optimal performance and preventing larger, costlier problems down the line. But, routine maintenance isn't always so routine. Unforeseen complications can disrupt schedules, inflate expenses, and even hinder productivity. It's therefore essential to be prepared with a robust plan to address these unavoidable hurdles. And that is a pivotal point in our discussion.

Consider this: skipping routine maintenance is akin to a high-stakes gamble with your equipment. You might enjoy a period of success, but eventually, something will falter, and the cost of such a breakdown can be significant. Routine maintenance allows you to identify and correct potential problems before they escalate into major disruptions. It prolongs the lifespan of your equipment, boosts efficiency, and ensures smooth operation. Furthermore, it provides considerable savings over the long term by sidestepping expensive emergency repairs.

Now, let's examine the common obstacles that those in the maintenance field often face. Think of them as the familiar speed bumps on the road to operational efficiency:

- Unlock Hyungry Your Guide To Temporary Replacement Solutions

- Best Ftv Sites Your Ultimate Guide In 2024 Beyond

- Resource Constraints: Insufficient manpower or inadequate tools can significantly impede progress.

- Equipment Failures: Equipment can unexpectedly malfunction, often without prior warning, causing immediate disruption.

- Time Management: Fitting all maintenance tasks within a strict schedule poses a considerable challenge.

Beyond these common issues lie the unexpected challenges those that can catch you off guard and throw a wrench in your carefully laid plans. These can range from adverse weather conditions that disrupt outdoor work to supplier delays that leave you scrambling for alternative solutions. Successfully navigating these challenges necessitates quick thinking, adaptability, and effective contingency planning.

Let's now turn our attention to a company called Ubetteme, which employs a unique approach to routine maintenance, focusing on efficiency and effectiveness. Ubetteme recognizes that maintenance is not just about ticking boxes; it's about ensuring every component works seamlessly with others. Ubetteme underscores the importance of a highly trained team, the use of the right tools, and the implementation of a robust maintenance strategy. The company acknowledges the value of technology in streamlining processes and improving overall outcomes.

Ubetteme's maintenance strategy is centered around proactivity rather than reactivity. They concentrate on identifying potential issues before they evolve into full-blown problems. This involves regular inspections, data analysis, and a commitment to continuous improvement. Ubetteme invests in training its staff, equipping them with the necessary skills and knowledge to handle any situation. Furthermore, they leverage technology to monitor equipment performance in real-time, enabling them to address issues promptly and effectively.

So, how do you effectively handle the unexpected? The answer lies in meticulous preparation. A well-defined plan can make all the difference when things dont go as planned. Begin by identifying potential risks and developing contingency plans for each. This might involve having backup equipment, maintaining extra supplies, or even having a team of standby technicians ready to respond. Communication is also crucial; keeping everyone informed prevents misunderstandings and ensures a coordinated response.

A resilient maintenance team is one that can adapt to changing circumstances and overcome any obstacle. This is achieved through a culture of continuous learning and improvement. Encourage your team to share knowledge, learn from their mistakes, and embrace new technologies. Investing in training and development is essential. The more skilled and knowledgeable your team is, the better equipped they will be to handle unexpected challenges. Furthermore, a well-trained team is more likely to spot potential issues before they become critical problems.

Technology has revolutionized the way we approach maintenance. From predictive analytics to IoT sensors, there's a wealth of tools available to help you stay ahead of the curve. Predictive maintenance, for instance, utilizes data analytics to forecast equipment failures, enabling proactive intervention. IoT sensors provide real-time monitoring of equipment performance, providing valuable insights into operational efficiency.

Implementing technology into your maintenance strategy may seem daunting, but it doesn't have to be. Start small by identifying the areas where technology can have the most significant impact. Then, gradually integrate new tools and systems into your processes. It's also crucial to involve your team in the transition. They are the ones who will be using the technology day-to-day, and their input can be invaluable in ensuring a smooth and successful integration. Moreover, getting your team on board early can help overcome any resistance to change.

Now, let's delve into the best practices for routine maintenance. These are the proven methodologies that can help you maximize the effectiveness of your maintenance efforts:

- Regular Inspections: Don't wait for something to break before you check it out. Regular inspections can catch issues early.

- Documentation: Maintain detailed records of all maintenance activities. This can help you identify patterns and plan for the future.

- Training: Invest in training your team to ensure they have the skills and knowledge needed to handle any situation.

Finally, cultivating a maintenance culture within your organization can significantly influence your success. This involves promoting a mindset of continuous improvement and encouraging everyone to take ownership of their role in the maintenance process. When everyone is invested in maintaining equipment and systems, you're more likely to achieve your goals. Moreover, a strong maintenance culture can lead to increased efficiency, reduced downtime, and improved overall performance.

- Explore Sexy Movies Full Hd Stream Enjoy Now

- Times Healthmagcom Your Ultimate Guide To A Healthier You